Installation Tips - Blackstone High Side Gondola

Blackstone Models HOn3 cars are great. They are pretty much ready to go right out of the box - but those stock 714 coupler really have to go.

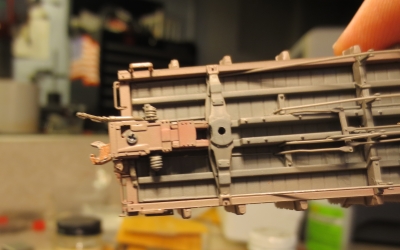

| Here's the starting point. It's typical of a Blackstone Models car. Wow! Look at that detail on the end of the car. Too bad the coupler doesn't meet the high standard set by the rest of the car. We can take care of that in no time. |  |

| We have to work on the bottom side of the car. The brake staff is fragile, so we must be careful not to damage it. I use an old modified kit box for this work. Cars with mostly flat tops can sit on the end of the box as shown. Cars with roofs that won't sit flat on their own go into the U shaped cut out in the center of the box. |  |

| Use jewelers screwdrivers to remove the trucks and coupler cover. |  |

| Here's a close up of the 714 coupler that comes factory installed. |  |

| Lift the 714 coupler up to remove it and here is what you will see. It's a good idea to hold your finger over it while you lift it off the post so the spring won't fly off into never never land. You can store the 714 coupler somewhere safe so you can re-install it at a later date if desired. |  |

| Push the Prototype Couplers RN87 coupler in place. The coupler mounting post on the Blackstone cars is usually larger in diameter a the top. This means the RN87 will need a little force to slip over the end of the post, but then it will be a nice fit. |  |

| For reliable coupling, it's important that the only resistance to side-to-side movement comes from the yet-to-be-installed friction spring. To check this, temporarily install the coupler cover. Then pick up the car and verify that the coupler falls when the car is held on its side. Then hold the car on its other side and verify the coupler falls to the other side. Basically, the coupler should just flop around until the friction spring is installed. |  |

|

Sometimes the coupler won't flop around as desired. This needs to be corrected. The mounting hole on the coupler will have to be enlarged slightly. This is easy to do with the Sergent Engineering RM40 tapered reamer. Insert the reamer from the bottom of the coupler and spin it to remove a little metal. Then perform the "flop" test again. The RM40 reamer requires much less force than its big brother the RM20 reamer (used for the EC87 couplers) does because its diameter is quite a bit smaller. Do be careful though. The RM40 is just as sharp! |

|

|

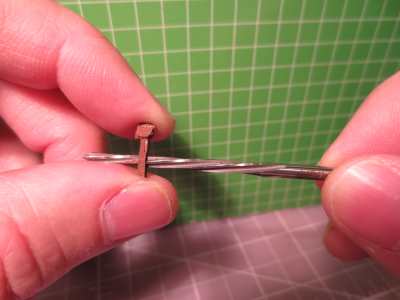

Once we pass the "flop" test, we are ready to install the friction spring. Start by placing the friction spring against the mounting post with its tail hanging over the rear of the coupler as shown in the picture. The springs are too small to be positioned with my fat fingers, but can be easily moved around with tweezers. Here's another trick you can use to position the springs that works even better: Lightly rub the tip of an xacto blade across the end of a Prototype Couplers MS uncoupling wand to magnetize the blade slightly. Now you can push the blade between the coils of the spring and the blade will stick to the spring. We always include extra springs, and will send more if you need them. You can also buy extra ball/spring packs so you always have them handy. |

|

| Now it's time to send the spring home. Here's what's happening in the picture: My left index finger is over the coupler and the end of the spring that is resting against the mounting post. With my other hand, I am using an xacto blade to compress the spring. As the spring is compressed, I push the spring into place with my index finger. This is much more difficult to desribe than it is to do. |  |

| Here is the spring after it's installed. |  |

| Reinstall the coupler cover and truck and move on to the other end of the car. |  |

| Here is the model reassembled and ready for action. Compare this picture the one at the top of the page. Pretty dramatic difference, huh? |  |