Installation Tips - Proto2000 Mather Box Car

This is another very nice Proto2000 car. I love that this cars come with a page of prototype information. Would I pay extra for that? You bet!

This conversion adapts a Prototype Couplers narrow shank coupler. This conversion demonstrates how to cut back the draft gear box of the narrow shank coupler to fit a particular car.

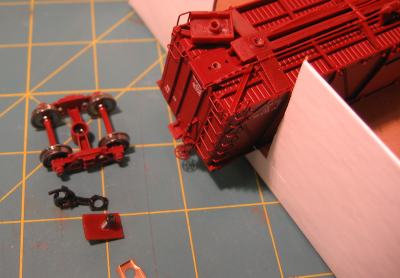

| Start by removing the truck and factory coupler. When the factory coupler comes off, the coupler can be removed as well. The two extra holes under the coupler box were not put there to allow us to install the EN87 as with Atlas cars. Instead, they are there to receive pins located on back of the coupler box so it will won't twist sideways. That's OK. We can use the leftmost hole to mount the EN87 anyway. It's in almost the perfect position to do so! |  |

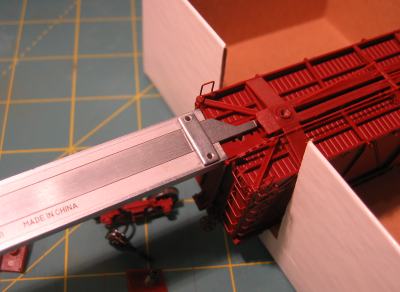

| Since the EN87 draft gear box is too long, it will have to be shortened a little. Use the depth measurement end of a set of dial calipers determine the draft gear box length needed. Once this distance is set on the calipers, use the locking screw to lock the calipers. |  |

| Now use the open jaws of the caliper and a hobby knife scribe a line on the EN87 draft gear box. We'll cut the box back to this length. |  |

|

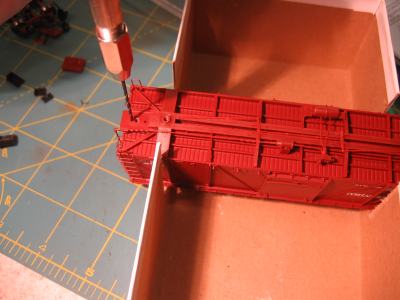

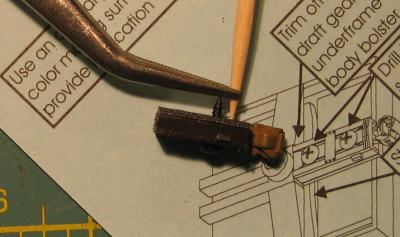

Use a razor saw to cut the coupler box on the line just scribed. Use a file to clean up the edge. |

|

| Since the draft gear box isn't going to stick out from the car at all, the lip on the top/front of the draft gear box will have to be trimmed away with a hobby knife. |  |

|

We'll be using the front hole to mount the EN87 coupler. This hole needs to be enlarged slightly to accept the mounting screw. The hole bottoms out at the steel weight of the car so don't expect to be drilling very deep. The #55 drill used here is the one included in our IFN installation kit for the EN87's. You can also get a full set if drills in "number" sizes from harbor freight. This drill set is much more useful for modeling than the fractional size sets you get at home depot, etc. You'll need a pinvise to hold the drill, too. Quality on these seems to vary greatly, so you might want a couple of different types. |

|

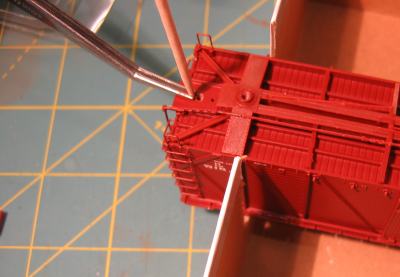

| Since hole for the coupler screw is shallow, we'll need to compare its depth to the depth needed for the screw. An easy way to do this is to put a toothpick in the hole and let in go all the way to the bottom of the hole. Then grab it with locking tweezers. The length of the toothpick extending from the tweezers is now the depth of the hole. |  |

| Now compare the depth of the hole with what is needed for the screw as shown in the picture. It looks to be very very close. Too close, it fact. Filing the sharp tip off the screw should make everything perfect though. |  |

| Now we can screw the EN87 coupler on with no fear that the screw will bottom out on the metal weight in the floor of the car. |  |

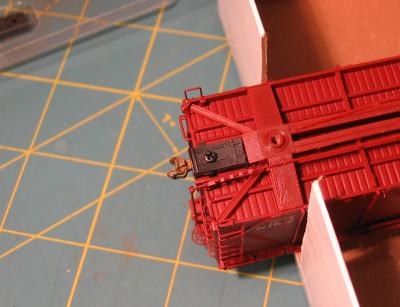

| Replace the trucks and we're done! |  |

| The narrow draft gear box is huge improvement over the factory box that we started with. |  |