Assembly Tips for the EC87 and EN87

Assembly Tip #1 - Lots of Light

The parts included in the Sergent Engineering coupler kits are tiny. Your work area should be well lit. We have successfully used a cheap telescoping magnifier light like those available from Harbor Freight. We also use a 50W halogen desk lamp from Target that is very nice because it doesn't keep falling on your head as you work.

Assembly Tip #2 - Anti-Roll-Away Surface

A white paper towel will keep the balls from going too far in case you drop them. Additionally, some folks have reported using an upside-down frisbee as a workspace to provide even more protection from loosing those balls.

Assembly Tip #3 - Non-magnetic Tweezers

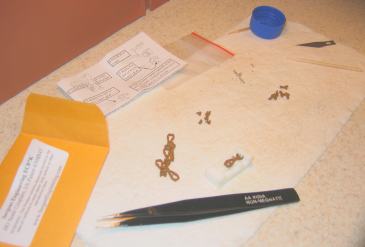

Don't pick up the balls with a wet finger. Skin oils will stick to the balls and the balls in turn will end up sticking in the coupler. Use tweezers instead. There are tweezers and then there are "non-magnetic" tweezers. Non-magnetic means that the tweezers won't become magnetic if they are exposed to a magnetic field (like the one surrounding the earth). You want the "non-magnetic" variety. Otherwise, the balls will stick to the tweezers and you'll be trying to shake them loose. The non-magnetic variety will almost always have something to that effect printed on them. Don't assume that stainless steel tweezers are non-magnetic because stainless steel is non-magnetic. Not all stainless steel is non-magnetic.

I found some nice non-magnetic tweezers at a train show. (You probably can't read the lettering on these in the picture; it says "Non-Megnatic" on these high quality babies.) I have also seen similar selections at flea markets. It's good to see how they feel in your hand before purchasing. You don't want tweezers that require significant force to operate. Too much force will cause the balls to fly away (you'll put your eye out!). If you don't typically attend train shows or flea markets, you can buy a set of good tweezers from McMaster-Carr PN 5669A12. These will set you back about 10 bucks by the time you pay shipping charges.

Assembly Tip #4 - What Type of Glue?

he adhesive needed to assemble the couplers should be a thick cyanoacrylate. Everyone seems to have there favorite brand. We use Zap-A-Gap. Some brands tend to have more aggressive vapors than others. These vapors can make their way to different parts of the coupler and actually bond to things you never intended (like the balls). If you have troubles, try a different brand of adhesive. Remember that this stuff does get old and becomes less effective with age. Its a good idea to use a Sharpie to write the date on the bottle when it is originally opened. After 9 months, its time to replace it.

Notice the soda bottle cap in the photo. This is used to contain a little squirt of glue which is dispensed one tiny drop at a time with a toothpick. The soda bottle cap keeps the glue from quickly drying out. It will usually last for hours. I can't remember where I learned that trick, but it really works. Try it. It's magic!

It's worth mentioning that the strength of the glue joints isn't really critical since the glue isn't load bearing. The glue's job is to keep the bottom cover in place, but the fit between the top and bottom parts is what bears the load of the train. You might have noticed that the shanks on the factory assembled EC87 and EN87 couplers are staked together. This is to speed the assembly process rather than for strength. You can duplicate this assembly method with a small punch if you like, but it won't make for a stronger coupler and it might make a subsequent disassembly task much more difficult.

Assembly Tip #5 - Disassembly with Acetone

At some point you are bound to assemble a coupler that just doesn't work right. Maybe you forgot to add the ball, or maybe there's a bit of foreign matter lodged in workings of the coupler. You'll need to disassemble the coupler to fix it. This is actually very easy. We keep jar of acetone nearby for this purpose. You can buy acetone at Wal-Mart or Home Depot in the paint department. Fingernail polish remover is mostly acetone as well, but don't use it because it usually has sticky moisturizers added. The wide mouth jar came from K-Mart and is particularly handy because it has a screw on lid. Acetone stinks. The lid is only removed when we need to add or remove couplers from the jar. Leave a troublesome coupler in the jar overnight and all traces of the adhesive will be gone by morning.

The acetone jar is also handy to clean your tweezers in. If they seem like they are starting to stick to the balls a little, then swirl them around in the acetone and wipe dry with a clean paper towel.

Assembly Tip #6 - Beware of Orange Bits

As a final step in the casting process, the castings are tumbled in walnut hulls to remove flash and improve the surface quality. Sometimes little bits of walnut hulls end up getting lodged in the castings - particularly in the hinge pin holes on the tiny knuckle castings. If left there, this material will cause the coupler to require more force than it should to open and close. After the plating process, the walnut hull bits turn bright orange and so are fairly apparent. You can see it in the two middle knuckles in the picture. You can easily pick the material out of these holes with the tip of a hobby knife. Just be on the lookout for it.

Assembly Tip #7 - Look for Casting Flash

Careful placement of parting lines on the Sergent couplers means you won't find much flash on the exterior of the coupler. However, it will show up sometimes at the ejector pin locations and at the inboard side of the knuckle. This flash normally breaks away during the break-in process, but a chance exists that the broken away flash might end up in a bad place like the ball seat where the ball goes when the coupler is in the locked position. An equally bad place might be behind the knuckle level. A quick examination of the castings will show if the flash needs to be removed. The drawings show where to look for the flash on the knuckle and top castings. A quick scrape with a hobby knife will remove the flash during assembly.

If you have an assembled coupler that doesn't seem to be operating correctly, there is a good chance that stray flash is floating around in the workings of the coupler. If you have a source of compressed air, you can usually blow it out without disassembling the coupler.

Assembly Tip #8 - Lost Instruction Sheet?

You can download a pdf file of the EN87 instruction sheet here. The EC87 instruction sheet is similar.